Predictive maintenance,asset utilization

STREAMLINED DATA

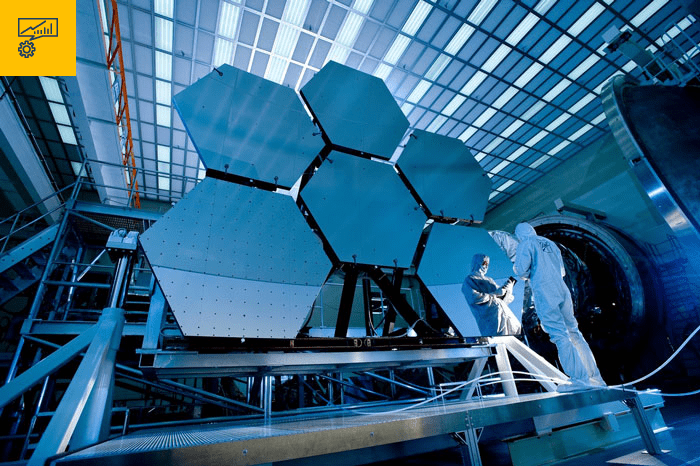

Predictive Maintenance & Early Warning Systems

Manufacturing or process plants rely on the automation and efficiency of complex equipment. Unexpected failures can grind operations to a halt, losing time and costing valuable revenue.

These complex machines generate massive amounts of data that can be mined and understood.

From food packaging plants to high-end chip manufacturers or life saving pharmaceuticals, Xpanse deploys systems allowing an understanding of the root-cause of failures and time-critical alters if the processes are at risk.

MACHINE LEARNING

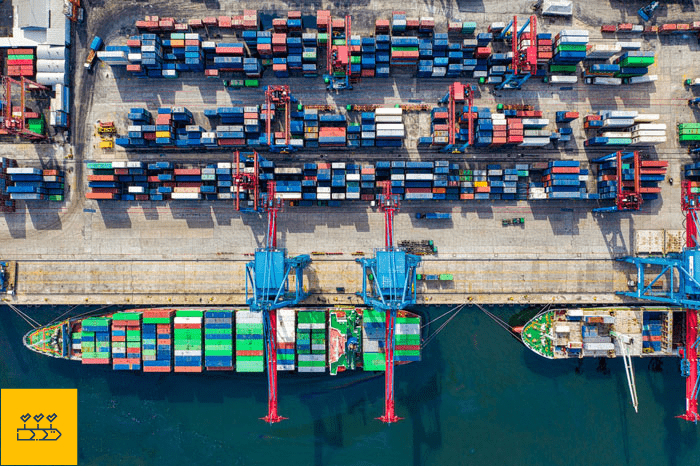

Bottleneck Forecasting & Supply Optimization

Identifying bottlenecks and potential supply shortfalls can be a make or break difference in how a company adapts and optimizes the supply chain.

With rich data sources, companies can now employ Machine Learning to answer questions about the root causes for bottlenecks, predict their re-occurrence and mitigate with alternative solutions.

AI-DRIVEN MODELS

Predictive Quality

Save time and money by using AI -assisted quality predictions.

By observing and identifying patterns in the real-time data our Models are capable of accurately predicting when the processes need adjusting in order to maintain required quality.

“Xpanse AI is capable of independently designing and testing thousands of Features from raw sensor signals. It enables a new level of Data Science where models and insights are delivered within minutes instead of waiting weeks for manually executed projects.”

5/5

Kevin Breen

CEO of Cyberactive

Ready to get started?